Sprocket Wheel in Wind Turbine Chain Drive Mechanisms

Introduction

In wind turbine chain drive mechanisms, the sprocket wheel plays a crucial role in transmitting power from the wind turbine blades to the generator. This article explores the various aspects of the sprocket wheel and its importance in wind turbine chain drive mechanisms.

The Structure of Sprocket Wheels

The sprocket wheel in wind turbine chain drive mechanisms consists of several key components, including the teeth, hub, and bore. The teeth are strategically designed to engage with the chain links, ensuring efficient power transfer. The hub is the central part of the sprocket wheel that connects to the shaft of the wind turbine. The bore is the hole in the center of the sprocket wheel that allows for easy mounting onto the shaft.

Types of Sprocket Wheels

There are several types of sprocket wheels used in wind turbine chain drive mechanisms, including single-strand sprocket wheels, double-strand sprocket wheels, and skip tooth sprocket wheels. Each type has its own advantages and is selected based on the specific requirements of the wind turbine system.

Importance of Sprocket Wheels in Wind Turbine Chain Drive Mechanisms

The sprocket wheel is a critical component in wind turbine chain drive mechanisms for several reasons. Firstly, it ensures smooth and efficient power transmission from the wind turbine blades to the generator. Secondly, it allows for easy adjustment of the gear ratio, enabling optimal performance of the wind turbine system. Lastly, it provides durability and reliability in harsh wind conditions, ensuring the longevity of the chain drive mechanism.

Installation and Maintenance

Proper installation and maintenance of the sprocket wheel are essential for the optimal performance of wind turbine chain drive mechanisms. Regular inspection and lubrication of the sprocket wheel teeth and chain are necessary to prevent wear and ensure smooth operation. Additionally, any damaged or worn-out sprocket wheels should be replaced promptly to avoid potential system failures.

Company Products and Introduction

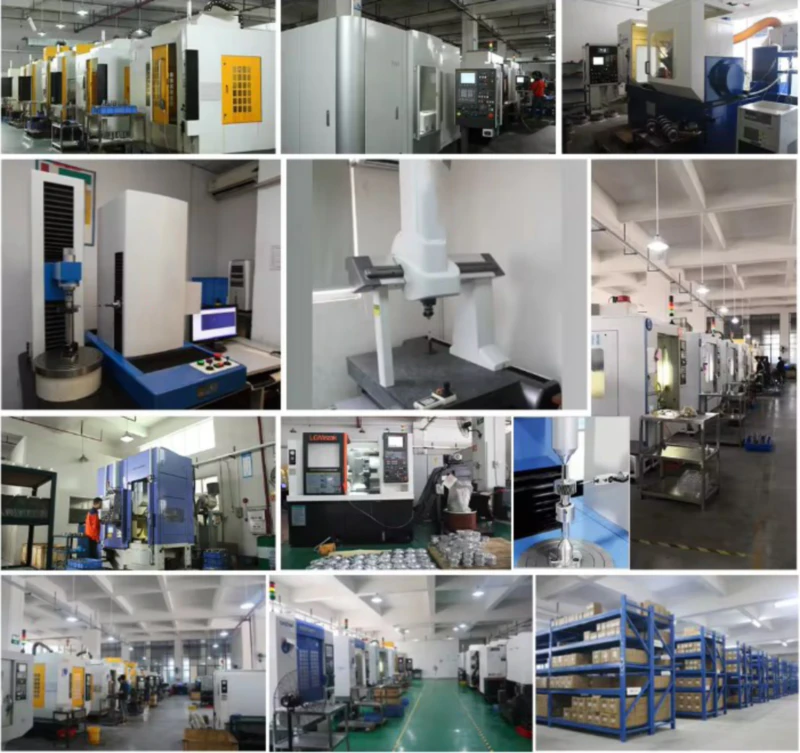

Our company, a leading player in the milling machine market in China, offers a wide range of high-quality products, including sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, and plastic chains. With 300 sets of various automatic CNC production equipment and fully automated assembly equipment, we are committed to delivering top-notch products, competitive prices, and excellent customer service.

Promotion of Our Company’s Products

We take pride in our superior products, competitive prices, and attentive service. We welcome customers to provide custom designs and samples, ensuring their specific needs are met. Explore our diverse range of sprocket wheels and other products today to experience the reliability and performance that sets us apart.

Author: Czh