Sprocket Wheel in Sawmill Chain Drive Mechanisms

Introduction

The sprocket wheel plays a crucial role in sawmill chain drive mechanisms. It is an essential component that facilitates the efficient power transmission from the motor to the chains, ensuring smooth and precise operation of the sawmill. In this article, we will explore the various aspects of the sprocket wheel and its significance in sawmill chain drive systems.

1. Understanding the Sprocket Wheel

The sprocket wheel, also known as a chainwheel, is a toothed wheel that meshes with the sawmill chains, enabling them to rotate and transfer power. It is typically made of high-quality steel or other durable materials to withstand the demanding working conditions in sawmill operations.

2. Types of Sprocket Wheels

There are several types of sprocket wheels used in sawmill chain drive mechanisms:

- Standard Sprocket Wheel: This is the most common type of sprocket wheel used in sawmills. It has a simple design with evenly spaced teeth.

- Tapered Sprocket Wheel: Tapered sprocket wheels are used to compensate for chain elongation over time, ensuring proper tension and alignment.

- Split Sprocket Wheel: Split sprocket wheels allow for easy installation and removal without disassembling the entire chain drive system.

- Flanged Sprocket Wheel: Flanged sprocket wheels have extended rims that prevent the chain from derailing.

3. Importance of Sprocket Wheel Design

The design of the sprocket wheel greatly influences the performance and durability of the sawmill chain drive system. Factors to consider in sprocket wheel design include:

- Teeth Profile: The shape and orientation of the teeth impact the smooth engagement and disengagement of the chains.

- Number of Teeth: The number of teeth on the sprocket wheel affects the speed and torque of the chains.

- Material Selection: Choosing the right material ensures the sprocket wheel’s ability to withstand high loads, abrasion, and corrosion.

- Heat Treatment: Proper heat treatment enhances the hardness and strength of the sprocket wheel, improving its overall performance.

4. Sprocket Wheel Maintenance

Maintaining the sprocket wheel is crucial for its long-term functionality and reliability. Here are some maintenance tips:

- Regular Inspection: Check for any signs of wear, damage, or misalignment on the sprocket wheel.

- Lubrication: Apply a suitable lubricant to reduce friction and prevent premature wear.

- Tension Adjustment: Ensure the proper tension of the chain to avoid excessive stress on the sprocket wheel.

5. Conclusion

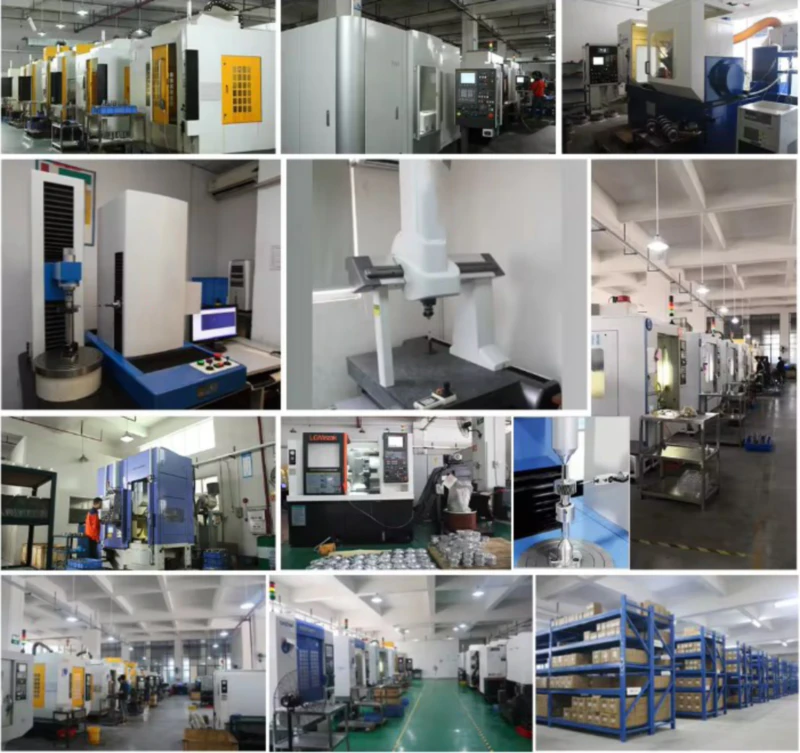

The sprocket wheel is an integral part of sawmill chain drive mechanisms, providing reliable and efficient power transmission. Its design, material selection, and maintenance contribute to the overall performance of the sawmill. As a leading company in the Chinese milling machine market, we specialize in manufacturing high-quality sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, and plastic chains. With 300 sets of advanced CNC production equipment and automatic assembly devices, we guarantee superior products, competitive prices, and excellent service. Contact us today for customized solutions.

Product Showcase

Author: Czh