Sprocket Wheel in Roller Chains

Introduction

Roller chains are widely used in various industries, providing a reliable and efficient means of power transmission. At the heart of roller chains lies the sprocket wheel, a crucial component that ensures smooth and precise movement. In this article, we will explore the role of the sprocket wheel in roller chains and its importance in different applications.

The Anatomy of a Sprocket Wheel

The sprocket wheel consists of several key elements that contribute to its functionality:

- Teeth: The sprocket wheel features precisely engineered teeth that engage with the chain, transferring power and facilitating motion.

- Pitch Diameter: The pitch diameter determines the effective size of the sprocket wheel and is directly related to the chain’s pitch.

- Bore: The central hole of the sprocket wheel allows it to be mounted on a shaft, ensuring rotational motion.

- Hub: The hub connects the sprocket wheel to the shaft, providing stability and support.

The Importance of Sprocket Wheel Design

Proper sprocket wheel design is essential for optimal chain performance and longevity. Factors such as tooth profile, material selection, and surface treatment significantly impact the overall efficiency and durability of the roller chain system.

1. Tooth Profile

The tooth profile plays a crucial role in smooth chain engagement and reduced noise generation. Various tooth profiles, including involute, cycloidal, and trapezoidal, are used depending on the specific application requirements.

2. Material Selection

The choice of material for the sprocket wheel depends on factors such as load capacity, operating conditions, and environmental factors. Common materials used include hardened steel, stainless steel, and high-strength alloys.

3. Surface Treatment

Surface treatment techniques, such as heat treatment, coating, and plating, enhance the wear resistance and corrosion resistance of the sprocket wheel. This ensures prolonged service life and reduced maintenance requirements.

Applications of Sprocket Wheel in Roller Chains

The versatility of roller chains, combined with the reliable performance of sprocket wheels, makes them suitable for various applications:

- Industrial Machinery: Sprocket wheels are extensively used in machinery such as conveyors, packaging equipment, and assembly lines, enabling precise and efficient movement of materials and components.

- Automotive: In automotive applications, roller chains with sprocket wheels drive timing systems, camshafts, and other critical engine components, ensuring optimal performance and reliability.

- Agricultural Machinery: Sprocket wheels are vital components in agricultural machinery like tractors and combines. They facilitate the smooth operation of farm equipment, enabling tasks such as harvesting, planting, and tilling.

Conclusion

The sprocket wheel is an integral part of roller chains, providing the necessary power transmission and ensuring precise movement in various industries. Proper design, material selection, and maintenance are key to maximizing the efficiency and durability of roller chain systems.

Application Scene

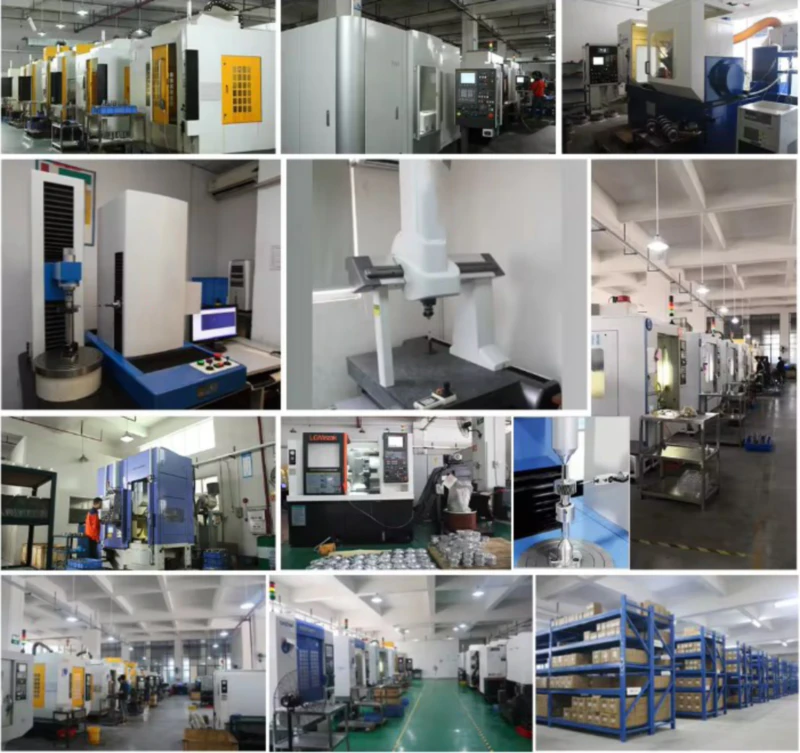

About Our Company

Author: Czh

Our company is a leading player in the milling machine market in China. We specialize in the production of high-quality sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With 300 sets of various automatic CNC production equipment and automated assembly devices, we ensure the precision and reliability of our products.

We take pride in offering superior products, competitive prices, and attentive service to our customers. Customization based on customer designs and samples is also available. We welcome you to experience the quality and versatility of our products.