Sprocket Wheel in Material Handling Chain Conveyors

Introduction

In material handling chain conveyors, sprocket wheels play a crucial role in facilitating the smooth movement of goods. These wheels, also known as chain sprockets, are designed to engage with the links of a chain, allowing it to move along the conveyor system. With their precision engineering and durable construction, sprocket wheels ensure efficient and reliable transportation of materials in various industries.

The Importance of Sprocket Wheels

Sprocket wheels are an integral component of material handling chain conveyors. They provide the necessary traction and drive power to move the chain, enabling the transfer of goods from one point to another. The design and selection of sprocket wheels significantly impact the overall performance and efficiency of the conveyor system.

Types of Sprocket Wheels

1. Standard Sprocket Wheels: These sprocket wheels have a uniform pitch diameter and tooth profile, making them suitable for general-purpose applications.

2. Idler Sprocket Wheels: Idler sprockets are used to guide the chain and maintain tension while not directly driving it. They are commonly found in curved sections or areas with limited space.

3. Split Sprocket Wheels: Split sprocket wheels consist of two separate halves that can be easily assembled or disassembled without removing the chain. They provide convenience for maintenance and replacement.

4. Specialty Sprocket Wheels: Specialty sprocket wheels are designed for specific applications, such as those requiring high-speed operation, corrosion resistance, or noise reduction.

5. Customized Sprocket Wheels: Manufacturers offer customization options to meet unique requirements, including different tooth profiles, materials, and sizes.

Advantages of Sprocket Wheels in Material Handling

– Enhanced Efficiency: Sprocket wheels minimize slippage and ensure a consistent transfer of power, resulting in improved overall system efficiency.

– Durability and Longevity: High-quality sprocket wheels are made from robust materials, increasing their resistance to wear, fatigue, and corrosion.

– Precise Chain Engagement: The accurate tooth profile and pitch diameter of sprocket wheels allow for optimal chain engagement, reducing the risk of malfunctions and chain derailment.

– Smooth Operation: Well-designed sprocket wheels contribute to a smooth, vibration-free operation, minimizing noise and extending the lifespan of the conveyor system.

Application of Sprocket Wheels

Sprocket wheels find extensive use in a wide range of industries, including:

– Automotive: Sprocket wheels are utilized in automotive assembly lines to transport parts and components.

– Food and Beverage: Conveyor systems equipped with sprocket wheels efficiently handle food and beverage products during processing and packaging.

– Manufacturing: Sprocket wheels ensure the smooth movement of materials in manufacturing facilities, aiding in production efficiency.

– Logistics and Warehousing: Sprocket wheels enable the seamless transportation of goods in warehouses and distribution centers.

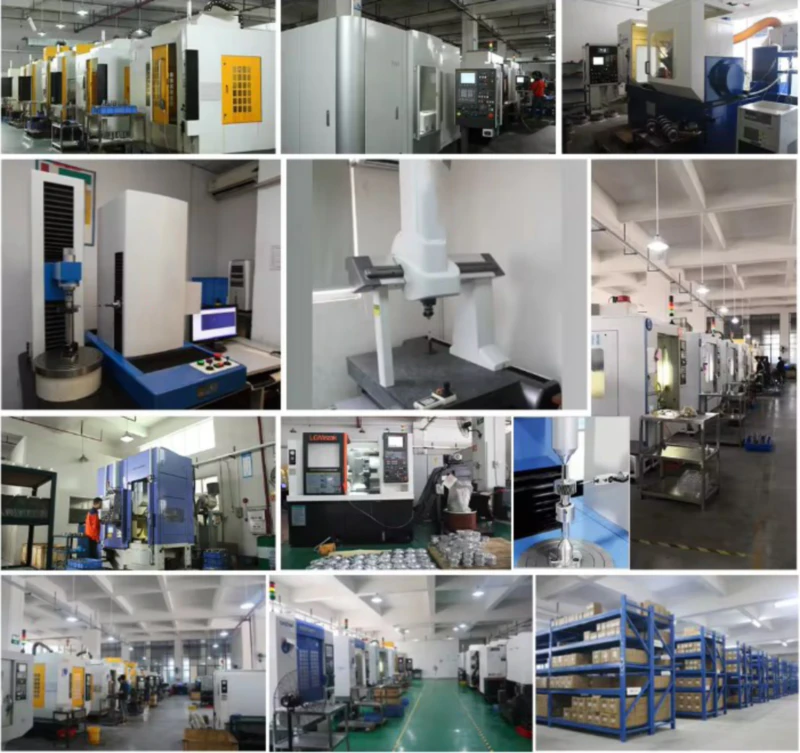

Company Promotion and Introduction

At our company, we are a leading provider of milling machine solutions in the Chinese market. Our extensive product range includes sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With 300 sets of various automated CNC production equipment and fully automated assembly equipment, we pride ourselves on delivering high-quality products, competitive prices, and excellent customer service.

Feel free to contact us for customized solutions based on your specific requirements. Together, we can optimize your material handling chain conveyor system for maximum efficiency and productivity.

Factory Image

Author: Czh