Sprocket Wheel in Marine Propulsion Chain Drives

Introduction

In the world of marine propulsion, the sprocket wheel plays a crucial role in chain drives. This vital component ensures the efficient transfer of power from the engine to the propeller, enabling smooth and reliable operation. In this article, we will explore the various aspects of the sprocket wheel in marine propulsion chain drives, from its design and function to its applications and benefits.

1. Understanding the Sprocket Wheel

The sprocket wheel is a specialized gear that features a series of evenly spaced teeth or cogs, which interlock with the links of a chain. Its primary purpose is to transmit rotational motion and power from one shaft to another, allowing for the controlled transfer of energy in marine propulsion systems.

2. Types of Sprocket Wheels

There are several types of sprocket wheels used in marine propulsion chain drives, each designed to meet specific requirements. These include:

2.1. Toothed Sprocket Wheels

Toothed sprocket wheels are the most common type used in marine propulsion systems. They feature teeth that are specially shaped and positioned to engage with the chain, ensuring a secure and efficient power transmission.

2.2. Idler Sprocket Wheels

Idler sprocket wheels are used to guide and maintain tension in the chain, preventing sagging or skipping. They are typically positioned between the driving and driven sprocket wheels and help ensure smooth and reliable operation.

2.3. Double Pitch Sprocket Wheels

Double pitch sprocket wheels are designed for chains with larger pitch sizes. They feature teeth with a different shape and spacing compared to standard sprocket wheels, accommodating the larger chain pitch and ensuring optimal performance.

3. Benefits of Sprocket Wheels in Marine Propulsion Chain Drives

The use of sprocket wheels in marine propulsion chain drives offers several benefits:

3.1. Precise Power Transmission

Sprocket wheels ensure precise power transmission, allowing for efficient energy transfer from the engine to the propeller. This leads to improved performance and optimized fuel consumption.

3.2. Reliable Operation

With their robust design and secure engagement with the chain, sprocket wheels provide reliable operation in marine propulsion systems. They can withstand high torque and rotational speeds, ensuring smooth and uninterrupted power transmission.

3.3. Easy Maintenance

The design of sprocket wheels enables easy maintenance and replacement. With proper lubrication and periodic inspection, the sprocket wheel can have a long service life, minimizing downtime and maintenance costs.

4. Applications of Sprocket Wheels in Marine Propulsion

Sprocket wheels are widely used in various marine propulsion applications, including:

4.1. Ships and Vessels

Sprocket wheels are integral components in the propulsion systems of ships and vessels of all sizes. They ensure efficient power transmission, enabling smooth navigation and maneuverability.

4.2. Offshore Platforms

Offshore platforms rely on sprocket wheels to transfer power from the engines to the propellers, facilitating the transportation of personnel and equipment to and from the offshore sites.

4.3. Fishing Boats

Sprocket wheels play a vital role in the propulsion systems of fishing boats, enabling efficient and reliable operation during fishing expeditions and transportation of catch.

Conclusion

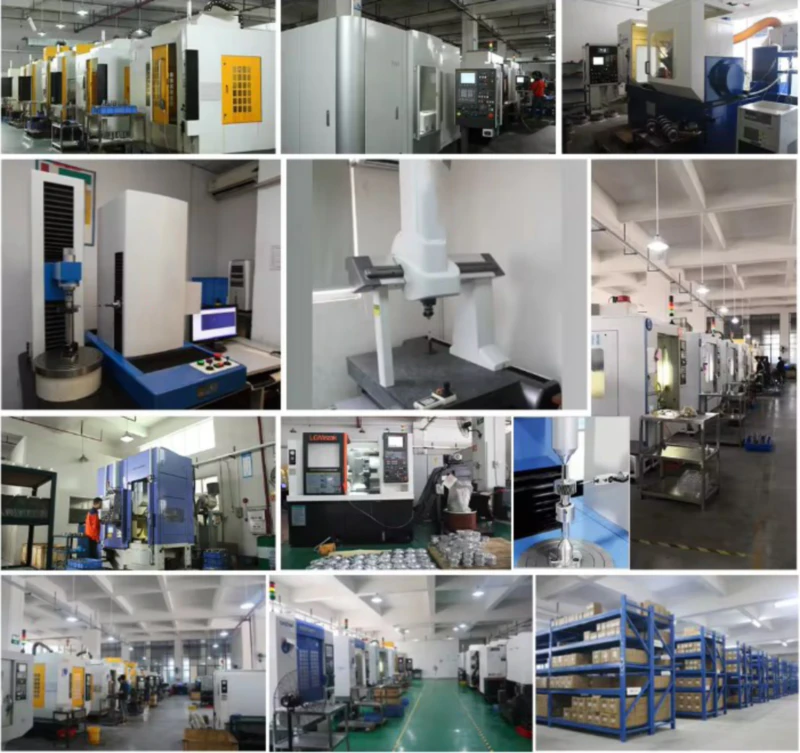

With their design precision and reliable performance, sprocket wheels are essential components in marine propulsion chain drives. They ensure efficient power transmission, reliable operation, and easy maintenance. Our company, a leader in the milling machine market in China, provides high-quality sprocket wheels, sprocket chains, motorbike sprockets, and more. With our state-of-the-art production facilities and dedication to customer satisfaction, we offer superior products, competitive prices, and excellent service. Welcome to customize your requirements with us.

Author: Czh