Sprocket wheel in conveyor systems

Introduction

In conveyor systems, the sprocket wheel plays a crucial role in ensuring the smooth and efficient movement of materials. With its unique design and functionality, the sprocket wheel is an essential component that enables the seamless operation of conveyor systems.

1. Understanding the Sprocket Wheel

The sprocket wheel is a toothed wheel that engages with the links of the conveyor chain, providing the driving force for the movement of the materials. It is typically made of durable materials such as steel or alloy, ensuring its longevity and reliability in various industrial applications.

2. Types of Sprocket Wheels

2.1. Standard Sprocket Wheel

The standard sprocket wheel is the most commonly used type in conveyor systems. It features a fixed number of teeth and is suitable for applications with consistent load and speed requirements.

2.2. Adjustable Sprocket Wheel

The adjustable sprocket wheel offers flexibility in terms of adjusting the number of teeth. This feature allows for easy customization to accommodate different load and speed variations, making it ideal for applications with changing operational requirements.

3. Advantages of Using Sprocket Wheels

3.1. Efficient Power Transmission

The sprocket wheel ensures efficient power transmission from the motor to the conveyor system, minimizing energy loss and maximizing operational efficiency.

3.2. Enhanced Stability and Control

With its precise engagement with the chain links, the sprocket wheel provides stability and control, preventing slippage and ensuring smooth material movement.

3.3. Extended Lifespan

Due to their sturdy construction and high-quality materials, sprocket wheels have a longer lifespan, reducing the need for frequent replacements and maintenance.

4. Applications of Sprocket Wheels

Sprocket wheels find extensive use in various industries, including:

4.1. Manufacturing

Conveyor systems with sprocket wheels are widely utilized in manufacturing processes, facilitating the movement of raw materials, components, and finished products.

4.2. Warehousing and Distribution

In the warehousing and distribution sector, sprocket wheels enable efficient material handling, ensuring timely delivery and optimized logistics operations.

4.3. Mining and Construction

Conveyor systems equipped with sprocket wheels are crucial in mining and construction operations, assisting in the transportation of heavy materials and equipment.

5. Conclusion

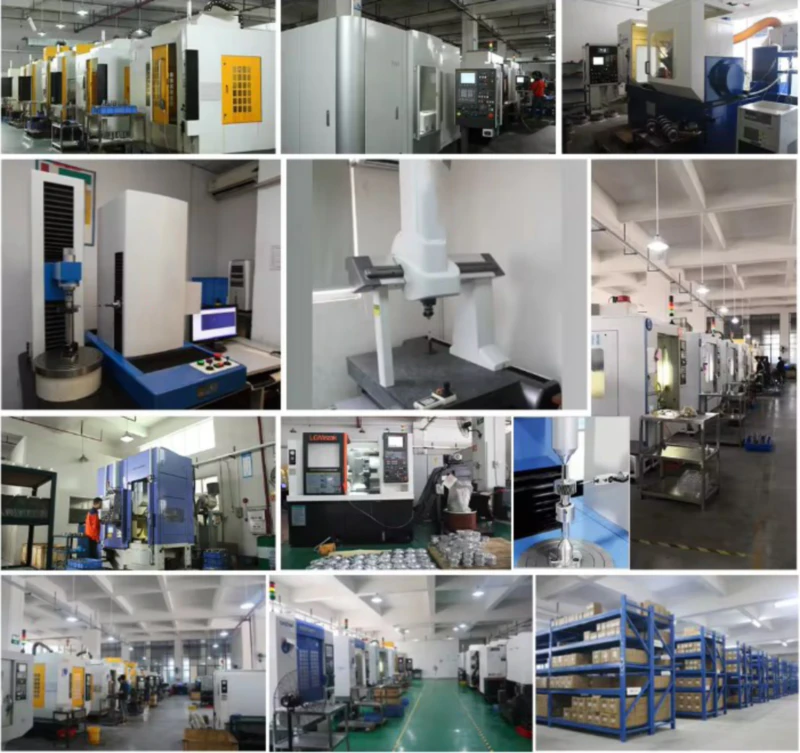

The sprocket wheel is an indispensable component in conveyor systems, providing efficient power transmission, stability, and control. With its various types and advantages, it caters to different operational requirements in a wide range of industries. As a leading company in the milling machine market in China, we specialize in the production of high-quality sprocket wheels, sprocket chains, motorbike sprockets, and more. With our state-of-the-art CNC production equipment and meticulous assembly processes, we guarantee superior products, competitive prices, and excellent customer service. We welcome customers to customize their requirements according to their specific needs.

Author: Czh