Sprocket wheel bore size tolerance monitoring

Introduction

In the field of mechanical engineering, sprocket wheels play a crucial role in various applications. Their precise design and manufacturing are of utmost importance to ensure optimal performance and longevity. One critical aspect that needs careful monitoring is the bore size tolerance of sprocket wheels. In this article, we will delve into the significance of monitoring bore size tolerance and its impact on overall sprocket wheel performance.

1. Understanding Bore Size Tolerance

Bore size tolerance refers to the acceptable deviation from the specified bore diameter of a sprocket wheel. It is a measurement that determines the permissible variation in the bore diameter to ensure proper fitment and functionality. Manufacturers must adhere to specific tolerance values to meet the desired performance standards of the sprocket wheel.

2. Importance of Monitoring Bore Size Tolerance

The monitoring of bore size tolerance in sprocket wheels is crucial due to the following reasons:

2.1 Ensuring Optimal Fit

Proper fitment between the sprocket wheel and corresponding shaft is essential for efficient power transmission. Monitoring bore size tolerance helps in maintaining the desired fit, reducing the chances of slippage or misalignment.

2.2 Minimizing Wear and Tear

By monitoring bore size tolerance, manufacturers can prevent excessive wear and tear in sprocket wheels. When the bore diameter exceeds the specified tolerance limits, it can lead to increased friction, resulting in premature wear and reduced lifespan of the sprocket wheel.

2.3 Enhancing Performance

Accurate bore size tolerance ensures optimal engagement between the sprocket wheel and the mating chain, leading to improved power transmission efficiency. This, in turn, enhances the overall performance of machinery and equipment.

3. Implementing Bore Size Tolerance Monitoring

Several methods can be employed to monitor bore size tolerance in sprocket wheels:

3.1 Coordinate Measuring Machine (CMM)

CMM is a precision measurement device that can assess the bore diameter with high accuracy. By conducting periodic inspections using CMM, manufacturers can ensure that sprocket wheels conform to the desired bore size tolerance.

3.2 Optical Measurement Systems

Optical measurement systems utilize advanced imaging technology to measure the bore diameter. These non-contact measurement techniques provide quick and accurate results, facilitating efficient bore size tolerance monitoring.

3.3 Statistical Process Control (SPC)

SPC involves the collection and analysis of data during the manufacturing process. By monitoring the bore size tolerance at various stages of production, manufacturers can identify and rectify any deviations, ensuring consistent quality control.

4. Conclusion

Monitoring bore size tolerance is a critical aspect of the sprocket wheel manufacturing process. It ensures optimal fit, minimizes wear and tear, and enhances overall performance. By implementing various monitoring methods such as CMM, optical measurement systems, and SPC, manufacturers can maintain the desired bore size tolerance and deliver high-quality sprocket wheels.

Company Promotion

Author: Czh

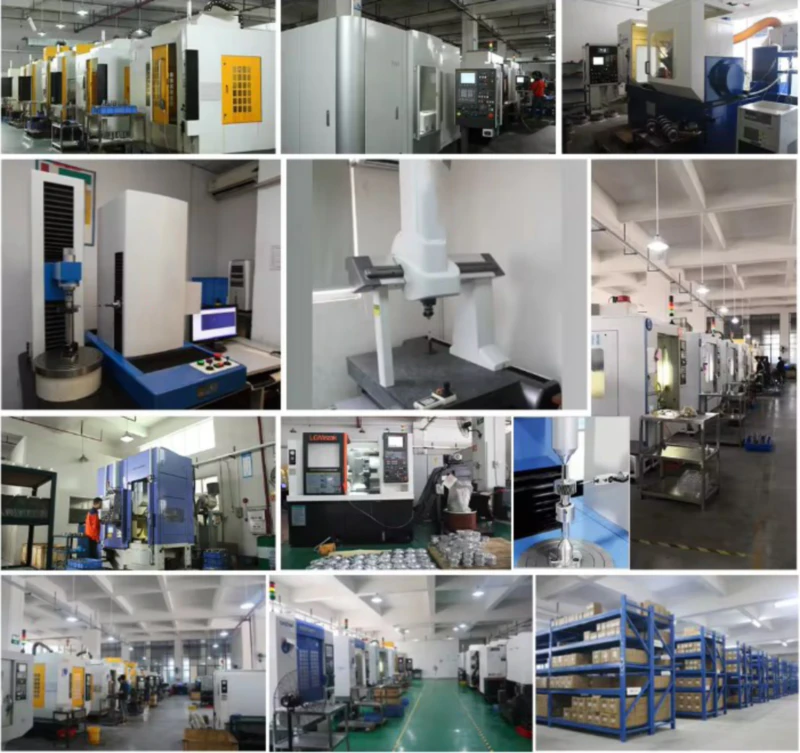

Our company is a leading player in the milling machine market in China. We specialize in manufacturing various sprocket wheel products, including sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, and plastic chains. With 300 sets of automatic CNC production equipment and fully automated assembly facilities, we ensure top-notch quality and precision.

Looking for custom-made sprocket wheels? Look no further! We welcome customers to provide us with their specific requirements, and we will deliver tailor-made solutions to meet their needs. Our products are known for their excellent quality, competitive pricing, and attentive customer service.