Sprocket Wheel Bore Size Tolerance Documentation

Introduction

In today’s blog post, we will explore the topic of sprocket wheel bore size tolerance documentation, and its importance in the manufacturing industry. Sprocket wheels play a critical role in various machinery and equipment, ensuring smooth rotational motion. Let’s dive into the details and understand the intricacies of this crucial parameter.

Understanding Bore Size Tolerance

When it comes to sprocket wheels, the bore size tolerance refers to the acceptable range of dimensional variation for the inner hole of the wheel. This tolerance is essential to ensure proper fitting and alignment with the shaft or axle. Manufacturers must adhere to specific standards and guidelines to maintain consistent quality and functionality.

The Impact of Bore Size Tolerance on Performance

The bore size tolerance directly affects the overall performance and reliability of sprocket wheels. A tight tolerance may result in difficulties during installation or cause excessive friction, leading to premature wear and tear. On the other hand, a loose tolerance can lead to misalignment and reduced power transmission efficiency. Achieving the correct bore size tolerance is crucial for optimal performance and longevity of the sprocket wheels.

Factors Affecting Bore Size Tolerance

Several factors contribute to the determination of bore size tolerance for sprocket wheels:

- Material Properties: Different materials have different thermal expansion coefficients, affecting the dimensional stability of the bore.

- Manufacturing Process: The method used to produce the sprocket wheel, such as casting or machining, can influence the achievable tolerance.

- Application Requirements: The specific application and the desired performance level will dictate the acceptable range of bore size tolerance.

Importance of Proper Documentation

Proper documentation of sprocket wheel bore size tolerance is critical for various reasons:

- Quality Control: Accurate documentation ensures consistency in manufacturing and helps identify any deviations from the specified tolerances.

- Interchangeability: Well-documented tolerances allow for easy replacement and interchangeability of sprocket wheels in different machinery.

- Troubleshooting: In case of any issues, having detailed documentation helps in diagnosing and addressing the problem efficiently.

Application Scenario

Let’s take a look at a real-life application scenario where sprocket wheel bore size tolerance plays a crucial role:

Company Promotion and Introduction

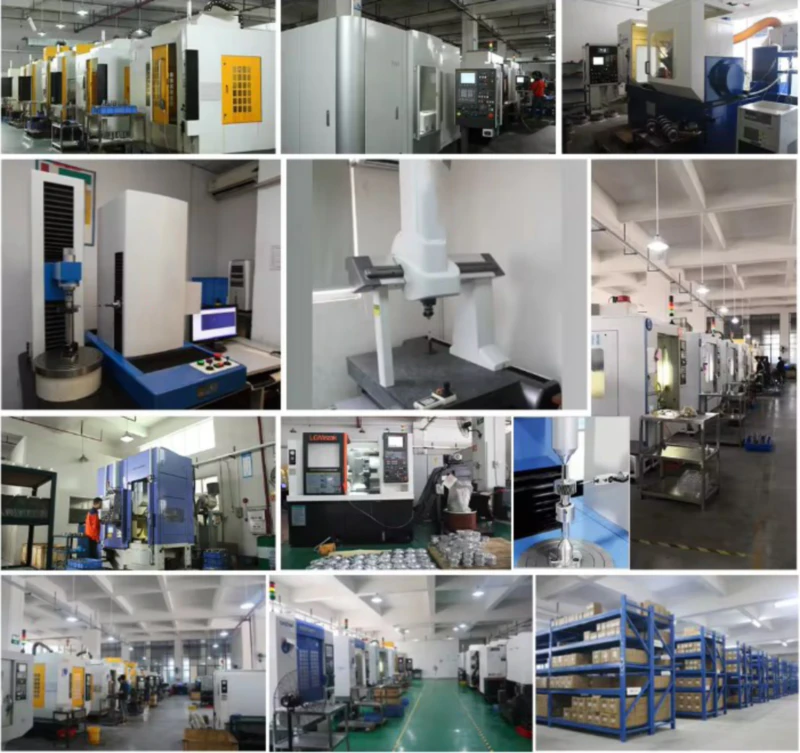

At our company, we are proud to be a leading player in the milling machine market in China. Our product range includes sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With 300 sets of various fully automated CNC production equipment and automatic assembly devices, we ensure the highest quality standards in our products.

We strive to provide our customers with superior products, competitive prices, and excellent service. Customization is also available based on customer requirements. We invite you to experience our offerings and benefit from our expertise in the field.

Author: Czh