Sprocket Wheel Keyway

In the world of engineering and machinery, the sprocket wheel keyway plays a crucial role in transmitting power and motion. This keyway, often overlooked, is an essential component that ensures the sprocket wheel is securely fastened to the shaft, preventing any slippage or loss of efficiency.

The Importance of Proper Keyway Design

A well-designed keyway is vital for ensuring the smooth and efficient operation of the sprocket wheel. By providing a precise and secure connection between the wheel and the shaft, the keyway prevents any unwanted movement or misalignment.

Keyway Materials and Considerations

When selecting the material for the keyway, it is important to consider factors such as strength, durability, and corrosion resistance. Common materials used for keyways include hardened steel, stainless steel, and bronze alloys.

Keyway Installation and Maintenance

Proper installation and regular maintenance are essential for ensuring the longevity and efficiency of the sprocket wheel keyway. It is important to carefully align the keyway with the shaft and use appropriate lubrication to reduce friction and wear.

Applications of Sprocket Wheel Keyway

The sprocket wheel keyway finds extensive use in various industries and applications. From industrial machinery to automotive and power transmission systems, the keyway ensures the reliable and efficient transfer of power and motion.

Conclusion

In conclusion, the sprocket wheel keyway is a crucial component in the world of engineering and machinery. Its proper design, installation, and maintenance are essential for ensuring the smooth and efficient operation of the sprocket wheel. With its wide range of applications and importance in power transmission, the keyway plays a significant role in various industries.

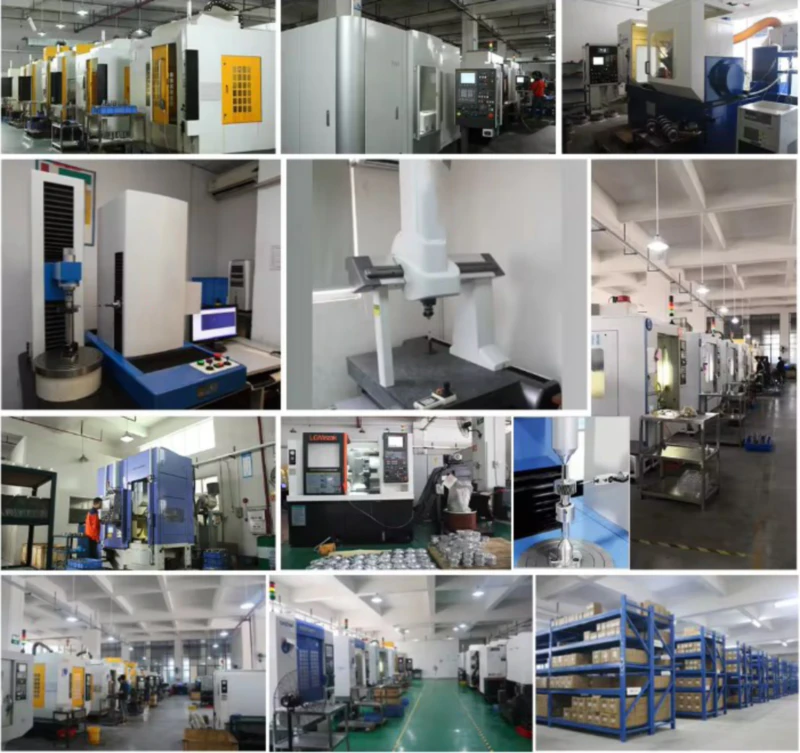

About Our Company

Our company holds a leading position in the milling machine market in China. We specialize in the production of high-quality sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With 300 sets of various automatic CNC production equipment and automatic assembly equipment, we ensure the precision and reliability of our products.

At our company, we take pride in offering superior products, competitive prices, and excellent customer service. We welcome customers to customize their products based on their specific requirements.

Author: Czh