Sprocket wheel in textile loom chain drives

Textile loom chain drives play a crucial role in the operation of textile looms. Among the key components in these chain drives is the sprocket wheel, which aids in the smooth and efficient movement of the chains. In this article, we will explore the significance of the sprocket wheel and its contribution to the overall performance of textile loom chain drives.

Importance of Sprocket Wheels

Sprocket wheels are vital in textile loom chain drives as they facilitate the proper engagement and movement of the chains. They are designed with precision to ensure smooth rotation and transfer of power from the motor to the loom. The teeth on the sprocket wheel interlock with the links of the chain, creating a reliable connection that enables the chain to move with accuracy and precision.

Types of Sprocket Wheels

There are various types of sprocket wheels used in textile loom chain drives, each with its unique characteristics and applications. Some commonly used types include:

1. Single-row Sprocket Wheels

Single-row sprocket wheels are the most basic type of sprocket wheels used in textile loom chain drives. They consist of a single row of teeth that engage with the chain links. These sprocket wheels are suitable for light to moderate loads and are commonly used in small-scale textile looms.

2. Double-row Sprocket Wheels

Double-row sprocket wheels have two parallel rows of teeth that engage with the chain links. They provide increased load-bearing capacity and are suitable for heavy-duty textile loom chain drives. These sprocket wheels offer enhanced stability and durability, making them ideal for large-scale textile production.

3. Tapered Sprocket Wheels

Tapered sprocket wheels have teeth that gradually decrease in size towards the center. This design allows for smooth engagement and disengagement of the chains, reducing wear and tear. Tapered sprocket wheels are commonly used in textile loom chain drives that require frequent stopping and starting.

Advantages of Sprocket Wheels

The use of sprocket wheels in textile loom chain drives offers several advantages:

- Efficient power transmission

- Accurate and precise movement of chains

- Reduced chain wear and elongation

- Improved overall performance of textile looms

Application of Sprocket Wheels in Textile Loom Chain Drives

Sprocket wheels are extensively utilized in textile loom chain drives across various textile industries. They are an integral part of both small-scale and large-scale textile looms, ensuring the smooth operation and reliable performance of the chain drives. Whether it’s a delicate weaving process or a high-speed production line, sprocket wheels play a crucial role in maintaining the efficiency and productivity of textile looms.

Company Introduction

Author: Czh

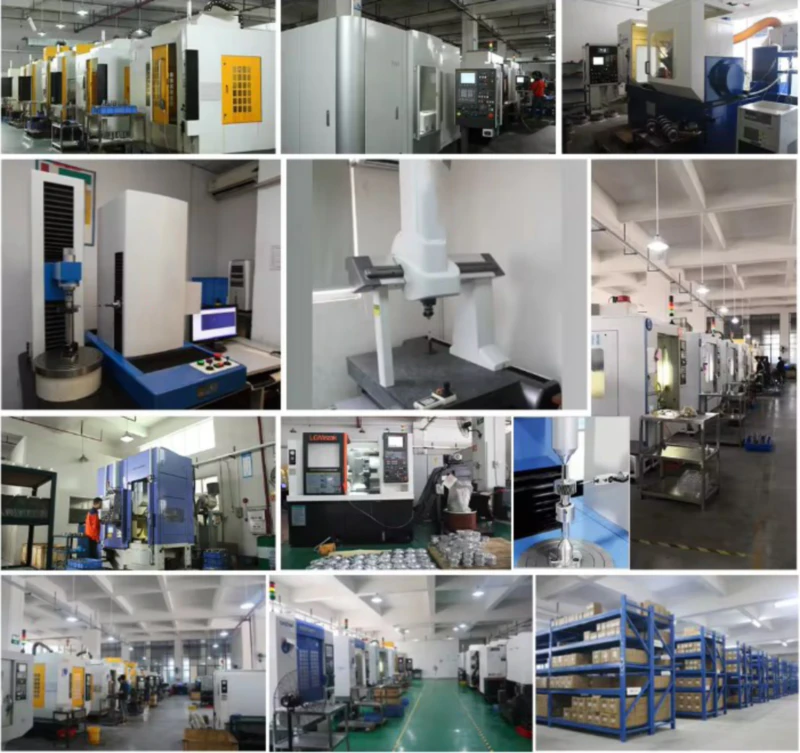

At our company, we are a leading provider in the milling machine market in China. Our wide range of products includes sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With 300 sets of various automatic CNC production equipment and fully automated assembly equipment, we ensure the highest quality and precision in manufacturing.

In addition to our exceptional products, we proudly offer competitive prices and excellent customer service. We welcome customers to provide us with their specific customization requirements. Our dedicated team is committed to meeting and exceeding customer expectations.

Thank you for reading our article on the importance of the sprocket wheel in textile loom chain drives. For more information or to inquire about our products, please contact us. We look forward to serving you!