Sprocket wheel in roller chain drive systems

Introduction

In roller chain drive systems, the sprocket wheel plays a crucial role in transmitting power between the driving and driven shafts. It is a toothed wheel that engages with the chain, enabling efficient power transfer. This article will explore the various aspects of sprocket wheels and their significance in roller chain drive systems.

Types of Sprocket Wheels

Sprocket wheels come in a variety of types, each designed for specific applications. Understanding the different types is essential for selecting the right sprocket wheel for your drive system. Let’s take a closer look at some common types:

1. Standard Sprocket Wheel

The standard sprocket wheel is the most commonly used type in roller chain drive systems. It has evenly spaced teeth and is suitable for general-purpose applications.

2. Tapered Sprocket Wheel

Tapered sprocket wheels are designed to accommodate tapered roller bearings. They provide better alignment and load distribution, enhancing the overall performance and longevity of the drive system.

3. Double Pitch Sprocket Wheel

Double pitch sprocket wheels have larger gaps between teeth, allowing them to engage with chains that have double the pitch of standard chains. These sprocket wheels are often used in conveyor systems.

4. Idler Sprocket Wheel

Idler sprocket wheels are used to guide the chain and maintain proper tension. They do not transmit power and are commonly found in systems with long chain spans.

Importance of Sprocket Wheel Design

The design of sprocket wheels greatly influences the performance and efficiency of roller chain drive systems. Factors such as tooth profile, pitch diameter, and material selection play a crucial role in achieving optimal power transmission. Here are some key considerations in sprocket wheel design:

1. Tooth Profile

The tooth profile determines how the chain engages with the sprocket wheel. Common tooth profiles include involute, cycloid, and modified profiles, each offering unique advantages in terms of smooth operation and load distribution.

2. Pitch Diameter

The pitch diameter of the sprocket wheel affects the speed ratio and torque transmission. Choosing the appropriate pitch diameter is essential for maintaining the desired rotational speed and power output.

3. Material Selection

Sprocket wheels are typically made from durable materials such as steel or cast iron. The material selection should consider factors like strength, wear resistance, and corrosion resistance to ensure long-lasting performance.

Applications of Sprocket Wheels

Sprocket wheels find widespread use in various industries and applications. Some notable applications include:

1. Industrial Machinery

Sprocket wheels are extensively used in industrial machinery, including conveyors, packaging equipment, and material handling systems. They facilitate efficient power transmission and reliable operation in demanding industrial environments.

2. Automotive Industry

In the automotive industry, sprocket wheels are employed in motorcycle drive systems, timing chains, and engine camshaft drives. Their precise tooth engagement and durability are crucial for maintaining optimal performance in vehicles.

3. Agricultural Machinery

Agricultural machinery, such as tractors and harvesters, rely on sprocket wheels for transmitting power to different components. The robust construction of sprocket wheels ensures reliable operation even in challenging farming conditions.

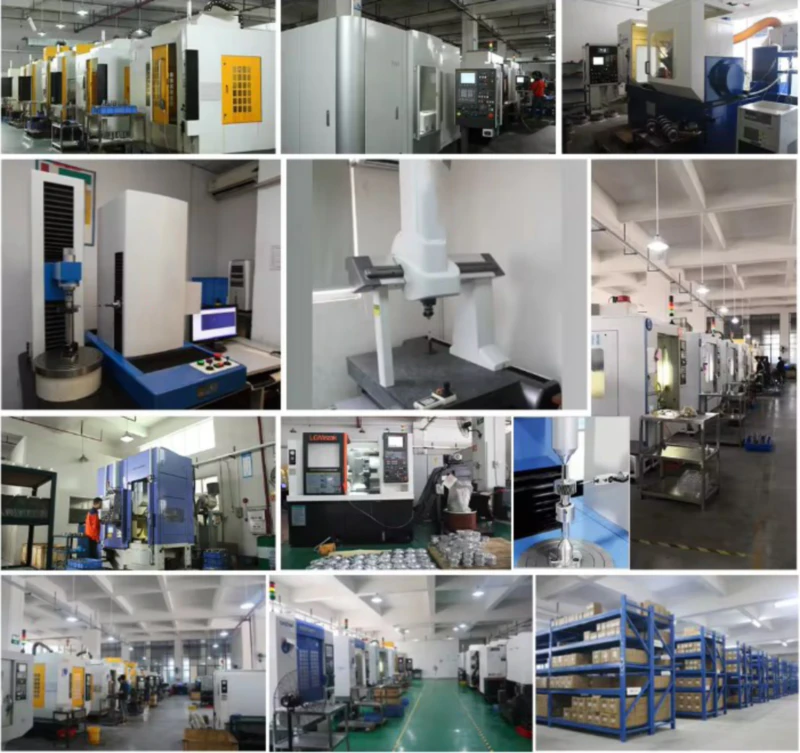

Company Introduction

Our company holds a leading position in the milling machine market in China. We specialize in manufacturing a wide range of products, including sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, and plastic chains. With 300 sets of various automatic CNC production equipment and automated assembly equipment, we ensure the highest quality standards in our products.

Promotion of Our Products

We take pride in offering high-quality products, competitive prices, and excellent customer service. We welcome customers to customize their orders according to their specific requirements. Please feel free to contact us for any inquiries or to place an order.

Author: Czh