Sprocket Wheel in Roller Chain Drive Mechanisms

Introduction

In roller chain drive mechanisms, the sprocket wheel plays a crucial role in transmitting power and motion. It is an essential component that enables smooth and efficient operation. This article will delve into the various aspects of sprocket wheels and their significance in chain drives.

1. Understanding Sprocket Wheels

Sprocket wheels are toothed wheels with evenly spaced teeth that mesh with the rollers of a chain. They are designed to transmit rotational motion and power between the driving and driven shafts. The precise configuration and tooth profile of the sprocket wheel greatly influence the performance of the chain drive system.

2. Types of Sprocket Wheels

There are several types of sprocket wheels, each serving specific purposes in different applications. Some common types include:

- Standard Sprocket Wheels

- Tapered Sprocket Wheels

- Idler Sprocket Wheels

- Split Sprocket Wheels

- Double Pitch Sprocket Wheels

3. The Role of Sprocket Wheel Teeth

The teeth on a sprocket wheel are designed to engage with the rollers of the chain, ensuring a positive power transmission. The shape, size, and spacing of the teeth determine the smoothness and efficiency of the chain drive system. Proper tooth design and alignment reduce noise, vibration, and wear.

4. Sprocket Wheel Materials

Sprocket wheels are commonly made from durable materials such as steel, cast iron, or even specialized alloys. The choice of material depends on the specific application requirements, including load capacity, wear resistance, and operating conditions.

5. Lubrication and Maintenance

Proper lubrication and maintenance are essential for the longevity and performance of sprocket wheels. Regular inspection, cleaning, and lubrication ensure smooth operation and minimize wear. It is crucial to follow the manufacturer’s recommendations for lubrication intervals and the type of lubricant to be used.

6. Applications of Sprocket Wheels

Sprocket wheels find extensive use in various industries and applications. Some notable applications include:

- Industrial machinery

- Automotive systems

- Agricultural equipment

- Conveyor systems

- Mechanical power transmission

Conclusion

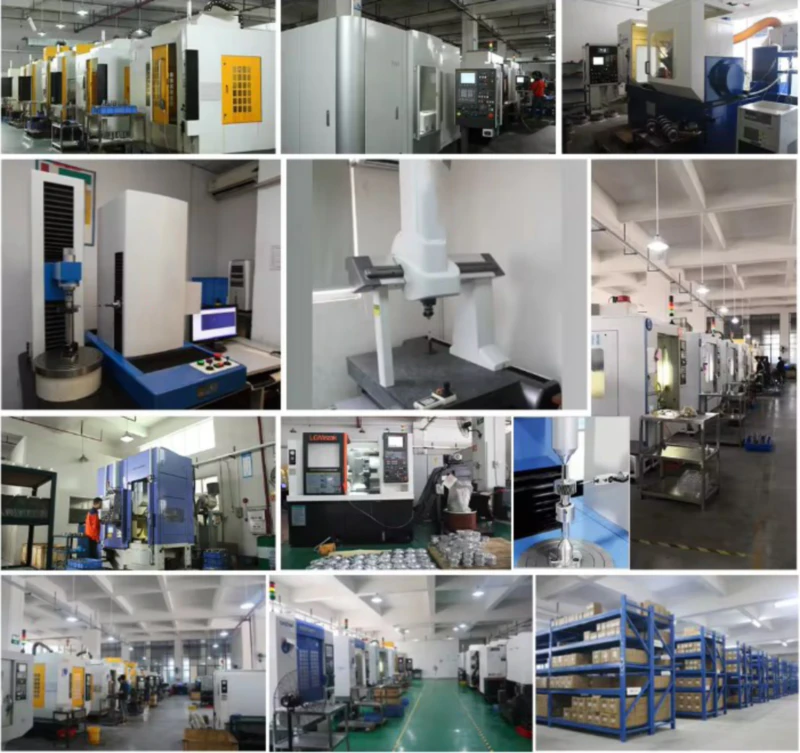

In conclusion, the sprocket wheel is a vital component in roller chain drive mechanisms, enabling efficient power transmission and motion. Understanding the different types, tooth profile, materials, and maintenance requirements of sprocket wheels is crucial for optimal system performance. Our company, a leading player in the milling machine market in China, specializes in manufacturing high-quality sprocket wheels, sprocket chains, motorbike sprockets, and other related products. With our state-of-the-art production facilities and dedication to customer satisfaction, we offer superior products, competitive prices, and excellent service. Please feel free to contact us for customized solutions.

Author: Czh