Exploring the Versatility of Sprocket Wheels in Power Tools

Introduction

Sprocket wheels are essential components in power tools, playing a crucial role in transmitting power and controlling the movement of machinery. With their intricate design and precise engineering, these small yet powerful gears are the unsung heroes behind the smooth operation of various power tools. In this article, we will delve into the world of sprocket wheels, uncovering their functionality, applications, and the benefits they offer to different industries.

Understanding Sprocket Wheels: A Detailed Overview

Sprocket wheels, also known as chain wheels or sprockets, are toothed wheels that engage with the teeth of a chain or belt. They provide power transmission by meshing with the chain or belt links, enabling rotary motion in machines. These wheels are commonly used in power tools such as chainsaws, motorbikes, milling machines, and various industrial equipment.

The Anatomy of a Sprocket Wheel

A sprocket wheel consists of several key components:

- Tooth Profile: The shape and size of the teeth determine the type of chain or belt that can be used with the sprocket wheel.

- Bore: The central hole in the sprocket wheel where it is mounted onto a shaft or axle.

- Hub: The hub is the center part of the sprocket wheel that connects to the shaft or axle.

- Flange: The flange prevents the chain or belt from slipping off the sprocket wheel.

Applications of Sprocket Wheels

Sprocket wheels find applications in a wide range of industries, thanks to their versatility and reliability. Let’s explore some of the key sectors where these power transmission components are extensively used.

1. Automotive Industry

In the automotive industry, sprocket wheels are commonly found in motorbikes and other vehicles with chain-driven mechanisms. These wheels facilitate smooth power transfer from the engine to the wheels, ensuring optimal performance and efficiency.

2. Industrial Machinery

Industrial machinery, such as milling machines and conveyor systems, heavily relies on sprocket wheels for transmitting power and controlling the movement of chains or belts. The robust design of sprocket wheels ensures reliable operation even in demanding industrial environments.

3. Power Tools

Power tools, including chainsaws and electric drills, utilize sprocket wheels to deliver precise and controlled rotational motion. The compatibility of sprocket wheels with chains and belts allows for efficient power transmission, enabling these tools to perform various tasks with ease.

Advantages of Sprocket Wheels

Sprocket wheels offer numerous advantages over other power transmission mechanisms. Here are some key benefits:

1. High Efficiency

Due to the positive engagement between the sprocket wheel teeth and the chain or belt, power loss is minimized, resulting in high transmission efficiency.

2. Precise Speed Control

Sprocket wheels allow for accurate speed control as the number of teeth on the wheel can be adjusted to achieve the desired output speed.

3. Durability and Reliability

Constructed from durable materials such as hardened steel or cast iron, sprocket wheels offer exceptional strength and resistance to wear and tear, ensuring long-lasting performance.

4. Flexibility

With a wide range of tooth profiles and sizes available, sprocket wheels can be tailored to specific applications, making them adaptable to various power transmission needs.

Company Promotion and Introduction

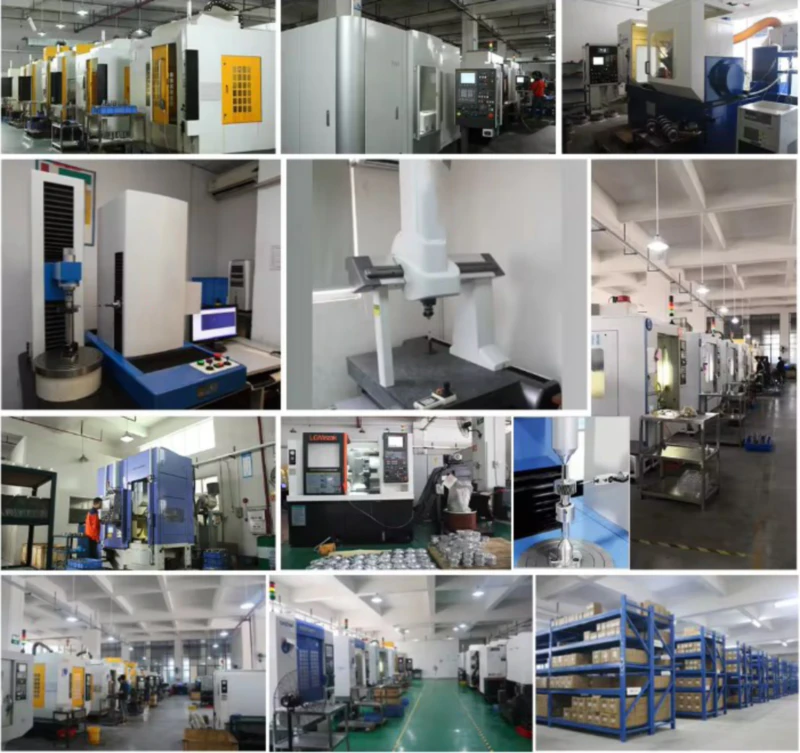

At [Company Name], we take pride in being a leading player in the milling machine market in China. Our extensive product range includes sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With 300 sets of state-of-the-art CNC production equipment and fully automated assembly systems, we ensure the highest quality standards for our products.

We are committed to providing superior products, competitive prices, and excellent customer service. Our company welcomes customization requests based on specific designs or samples provided by our valued customers. We strive to meet and exceed their expectations, delivering tailored solutions for their power transmission needs.

Author: Czh