Sprocket wheel in packaging machinery chain drives

Introduction

In the world of packaging machinery chain drives, the sprocket wheel plays a crucial role. Its significance cannot be understated as it ensures the smooth and precise movement of the entire chain system, allowing the packaging machinery to operate efficiently. In this article, we will delve into the various aspects of sprocket wheels and their importance in packaging machinery.

Understanding Sprocket Wheels

A sprocket wheel is a specialized gear with teeth or cogs that engage with the links of a chain. It is specifically designed to transmit rotational motion from the driving shaft to the driven shaft in packaging machinery chain drives. These wheels are usually made from high-quality materials such as hardened steel or alloy, ensuring durability and longevity.

The Function of Sprocket Wheels

Sprocket wheels serve two main functions in packaging machinery chain drives:

- Power Transmission: The primary function of a sprocket wheel is to transmit power from the driving shaft to the driven shaft. This ensures the smooth and synchronized movement of the entire chain system, allowing the packaging machinery to operate efficiently.

- Tension Control: Sprocket wheels also play a vital role in maintaining the tension of the chain. Proper tension is crucial to prevent the chain from slipping or derailing, ensuring optimal performance and reducing the risk of downtime or damage to the machinery.

Types of Sprocket Wheels

Sprocket wheels come in various types, each designed to meet specific requirements in packaging machinery chain drives. Some common types include:

- Single Strand Sprocket Wheels: These are the most basic type of sprocket wheels, consisting of a single set of teeth that engage with a single chain.

- Double Strand Sprocket Wheels: These sprocket wheels have two sets of teeth that engage with two parallel chains, providing increased power transmission and stability.

- Triple Strand Sprocket Wheels: Designed for heavy-duty applications, triple strand sprocket wheels accommodate three parallel chains, ensuring maximum power transmission and load-bearing capacity.

The Importance of Proper Sprocket Wheel Maintenance

Maintaining the sprocket wheels in packaging machinery chain drives is crucial for optimal performance and longevity. Regular inspection and maintenance can prevent issues such as wear, misalignment, or tooth damage. Proper lubrication and tension adjustment are also essential to ensure smooth operation and minimize the risk of breakdowns.

Conclusion

In conclusion, sprocket wheels play a vital role in packaging machinery chain drives, transmitting power and maintaining tension for optimal performance. Understanding the different types of sprocket wheels and their maintenance requirements is essential for the smooth operation of packaging machinery. With high-quality sprocket wheels and regular maintenance, packaging companies can ensure efficient production and minimize downtime.

Product Promotion

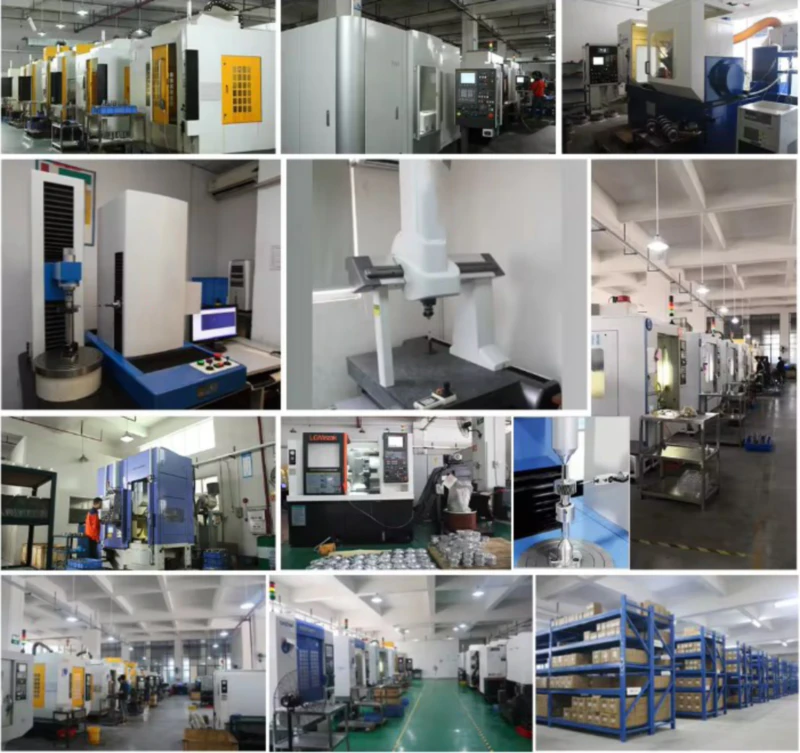

Our company is a leading provider of sprocket wheels and other chain-related products in the milling machine market in China. We offer a wide range of products, including sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With 300 sets of state-of-the-art automatic CNC production equipment and assembly facilities, we are committed to delivering high-quality products, competitive prices, and excellent customer service. We also offer customization services based on customer requirements. We invite customers to provide their designs and samples for tailored solutions.

Author: Czh