Sprocket Wheel in Escalator Chains

Introduction

In the field of escalator chains, one essential component that plays a crucial role in its smooth operation is the sprocket wheel. The sprocket wheel serves as a vital link between the escalator motor and the chains, ensuring the synchronized movement of the escalator steps. In this article, we will delve into the intricacies of the sprocket wheel and explore its significance in the escalator chain system.

Understanding the Sprocket Wheel

The sprocket wheel, also known as a chain wheel or chainring, is a toothed wheel that engages with the links of an escalator chain. It is typically made of durable materials such as hardened steel or alloy to withstand the constant stress and strain it faces during escalator operation. The design of the sprocket wheel is critical to ensure proper engagement with the chain, preventing slippage and ensuring smooth motion.

Key Features of the Sprocket Wheel

1. Tooth Profile: The teeth on the sprocket wheel are specially designed to match the shape and pitch of the escalator chain, allowing for efficient power transmission.

2. Pitch Diameter: The pitch diameter determines the size of the sprocket wheel and affects the speed and torque characteristics of the escalator. Proper sizing is crucial to maintain optimal performance.

3. Hub and Bore: The hub of the sprocket wheel provides a central mounting point for the wheel on the escalator motor shaft, while the bore allows for secure attachment.

4. Teeth Hardening: To enhance durability and prolong the lifespan of the sprocket wheel, the teeth are often hardened through heat treatment processes.

Importance of the Sprocket Wheel

The sprocket wheel plays a vital role in the overall performance and safety of an escalator chain system. Here are some key reasons why the sprocket wheel is of utmost importance:

1. Power Transmission: The sprocket wheel transfers power from the escalator motor to the chains, ensuring the synchronized movement of the steps.

2. Load Distribution: The sprocket wheel evenly distributes the load across the chain, preventing excessive stress on individual chain links and promoting longevity.

3. Noise Reduction: Properly designed and maintained sprocket wheels significantly reduce noise generated during escalator operation, enhancing the overall passenger experience.

4. System Efficiency: The precise engagement between the sprocket wheel and the chains minimizes energy losses, maximizing the overall efficiency of the escalator system.

Our Company and Products

Author: Czh

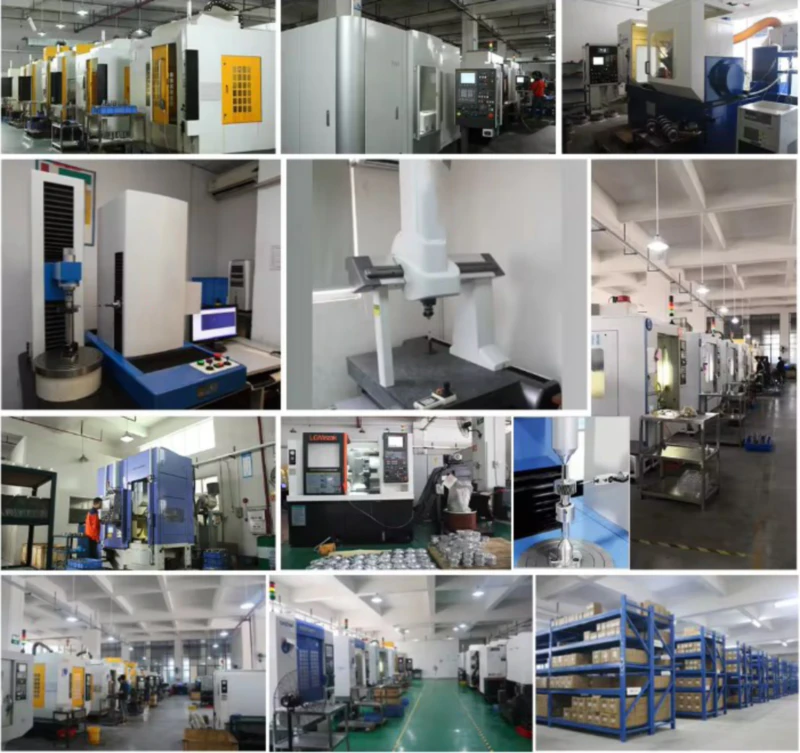

As a leading player in the milling machine market in China, our company offers a wide range of high-quality products, including sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With over 300 sets of fully automated CNC production equipment and automatic assembly facilities, we pride ourselves on delivering exceptional products and excellent service to our customers.

We invite customers to explore our customization options, allowing them to bring their specific requirements and designs to life. With our extensive expertise and dedication to customer satisfaction, we guarantee top-notch products, competitive prices, and attentive service.