Sprocket Wheel in Bicycle Chain Drive Systems

Introduction

In the world of bicycle chain drive systems, the sprocket wheel plays a crucial role. This small but powerful component is responsible for transferring power from the cyclist’s legs to the wheels, propelling the bicycle forward. In this article, we will explore the various aspects of sprocket wheels, their design, function, and their importance in achieving an efficient and smooth ride.

1. Understanding the Anatomy of a Sprocket Wheel

A sprocket wheel consists of several key components that work together to ensure optimal performance. These components include:

- Teeth: The teeth of the sprocket wheel are the most prominent feature. They are designed to engage with the chain and provide the necessary grip for power transfer.

- Hub: The hub is the central part of the sprocket wheel that attaches to the bicycle’s rear wheel hub.

- Mounting Holes: Sprocket wheels typically have multiple mounting holes to accommodate different gear ratios.

- Locking Mechanism: The locking mechanism ensures that the sprocket wheel remains securely attached to the hub and prevents it from slipping during operation.

2. The Role of Sprocket Wheels in Chain Drive Systems

Sprocket wheels are an integral part of the chain drive system in bicycles. They work in conjunction with the chain and other drivetrain components to transmit power efficiently from the cyclist to the wheels. The teeth on the sprocket wheel engage with the chain, causing it to rotate, which in turn rotates the rear wheel and propels the bicycle forward.

3. Design Considerations for Optimal Performance

The design of sprocket wheels plays a crucial role in achieving optimal performance and efficiency. Here are some key design considerations:

- Tooth Profile: The shape and profile of the teeth greatly impact the smoothness of gear shifting and power transfer. Different tooth profiles are used for specific purposes, such as climbing steep hills or achieving high speeds on flat terrain.

- Material Selection: Sprocket wheels are commonly made from durable materials such as steel or aluminum alloy. The material choice influences the strength, weight, and durability of the component.

- Number of Teeth: The number of teeth on a sprocket wheel affects the gear ratio and determines the effort required by the cyclist to pedal. Different gear ratios are suitable for different riding conditions.

4. Applications of Sprocket Wheels

Sprocket wheels find applications not only in bicycles but also in various other mechanical systems. Some common applications include:

- Motorcycles: Sprocket wheels are an essential part of motorcycle chain drive systems, providing power transfer from the engine to the rear wheel.

- Industrial Machinery: Sprocket wheels are widely used in industrial machinery, such as conveyor systems and milling machines, where precise power transmission is crucial.

Conclusion

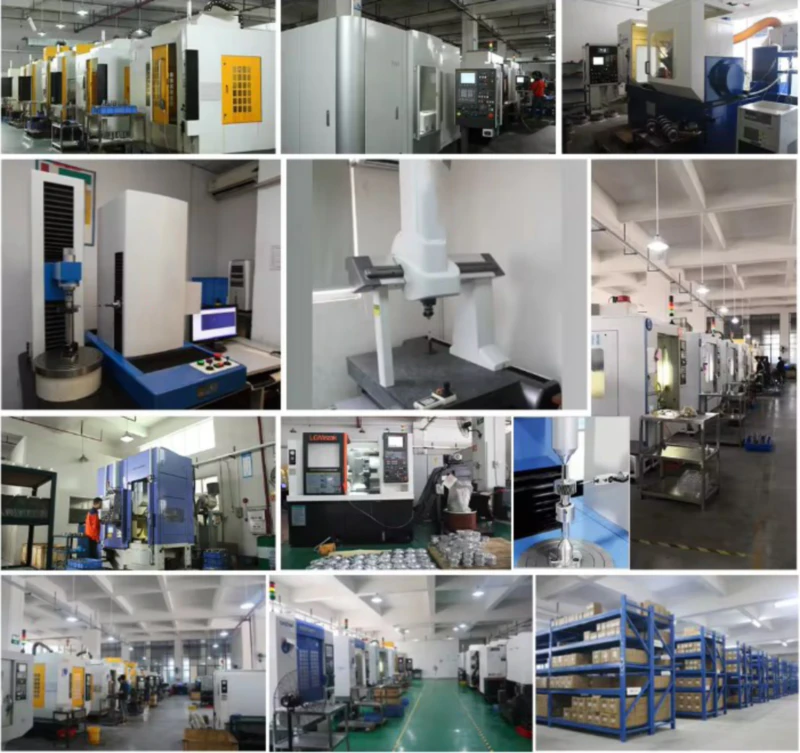

Sprocket wheels are indispensable components in bicycle chain drive systems, ensuring efficient power transfer and a smooth riding experience. With careful consideration of design and the use of high-quality materials, sprocket wheels contribute to the overall performance and functionality of bicycles. At [Company Name], we are a leading player in the milling machine market in China, offering a wide range of products, including sprocket wheels, sprocket chains, motorbike sprockets, and more. With our state-of-the-art manufacturing facilities and dedication to customer satisfaction, we take pride in delivering top-quality products at competitive prices. Contact us today for customized solutions tailored to your requirements.

Author: Czh