Sprocket Wheel Bore Size Tolerance Limit

Introduction

The sprocket wheel bore size tolerance limit is a crucial factor in the manufacturing of sprocket wheels. It determines the acceptable range of bore sizes for a sprocket wheel, ensuring proper fit and functionality when used in different applications.

Understanding Bore Size Tolerance

In the context of sprocket wheels, the bore size tolerance refers to the allowable deviation from the specified bore size. It accounts for manufacturing variations and ensures that sprocket wheels can be mounted securely on shafts while maintaining the necessary clearance.

Importance of Tolerance Control

Precise control of bore size tolerance is essential in sprocket wheel manufacturing. It guarantees compatibility with various shaft sizes and facilitates smooth power transmission in machinery and equipment.

The Impact of Tolerance Limit on Performance

The tolerance limit directly affects the performance and reliability of sprocket wheels. A tight tolerance limit ensures a snug fit, minimizing wobbling and reducing backlash. On the other hand, a loose tolerance limit allows for easier installation but may lead to compromised performance and premature wear.

Factors Affecting Tolerance Limit

Several factors influence the determination of the sprocket wheel bore size tolerance limit:

- Material properties

- Manufacturing process

- Design requirements

- Environmental conditions

Techniques for Tolerance Control

To maintain precise tolerance control, manufacturers employ various techniques:

- Advanced machining processes

- Strict quality control measures

- Accurate measurement and inspection methods

- Utilization of specialized machinery and equipment

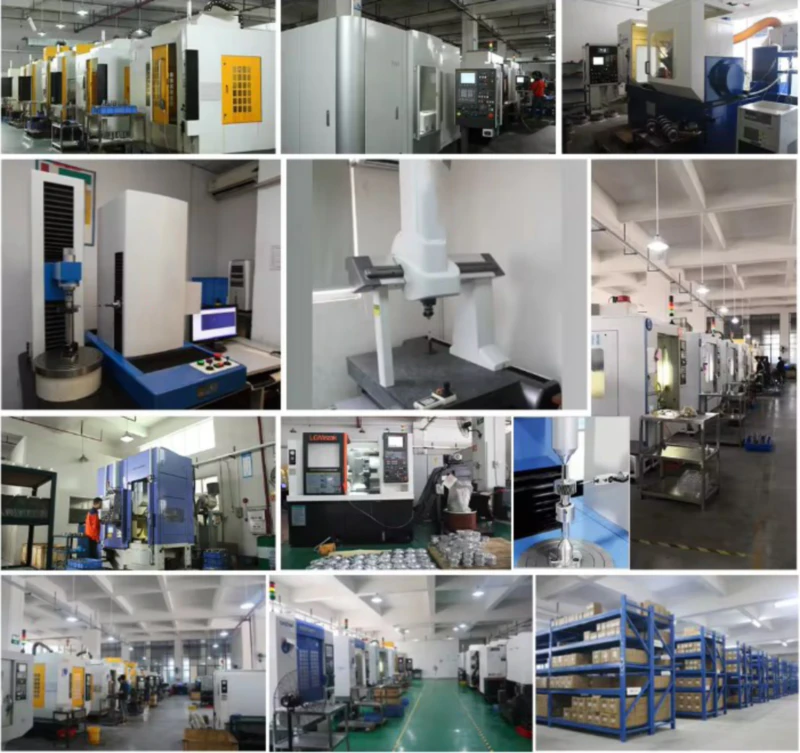

Our Company’s Expertise

As a leading player in the milling machine market in China, our company specializes in the production of various sprocket wheel products:

- Sprocket wheels

- Sprocket chains

- Motorbike sprockets

- Small sprockets

- Motor chains

- Bush chains

- Plastic chains

With 300 sets of fully automated CNC production equipment and assembly machinery, we ensure the highest quality standards and efficient production processes.

Promotion of Our Products

We take pride in offering top-notch products, competitive prices, and excellent customer service. We welcome customization based on client specifications, and our team is dedicated to meeting all customer needs.

About the Author

Author: Czh