Sprocket Wheel Bore Size Tolerance Inspection

Introduction

In the manufacturing industry, precision and accuracy are crucial for ensuring the proper functioning of mechanical components. One such component that requires careful inspection is the sprocket wheel bore size. The bore size tolerance of a sprocket wheel plays a vital role in its compatibility with other mechanical parts. In this article, we will delve into the importance of bore size tolerance inspection and its implications for various applications.

Understanding Bore Size Tolerance

Before we delve into the inspection process, it is essential to understand what bore size tolerance refers to. Bore size tolerance is the allowable deviation from the specified size of the sprocket wheel bore. It determines the range within which the bore size can vary without compromising the functionality of the sprocket wheel. Manufacturers must adhere to specific tolerance limits to ensure optimal performance and compatibility.

Importance of Bore Size Tolerance Inspection

Bore size tolerance inspection is a critical step in the manufacturing process of sprocket wheels. It ensures that the produced components meet the required specifications and are compatible with other mechanical parts. Failing to inspect the bore size tolerance can lead to various issues, such as:

- Poor fit between the sprocket wheel and shaft

- Increased wear and tear

- Reduced efficiency and performance

By conducting thorough bore size tolerance inspections, manufacturers can ensure that their sprocket wheels meet the necessary standards and deliver reliable performance in various applications.

Inspection Process

The inspection process for assessing bore size tolerance involves several precise steps. Here’s a breakdown of the procedure:

1. Measurement Equipment

To accurately measure the bore size tolerance, specialized measurement equipment is required. This includes:

- Digital Calipers

- Optical Comparators

- Micrometers

These tools allow for precise and reliable measurements, ensuring accurate assessment of the sprocket wheel bore size.

2. Sample Selection

Random samples are selected from the production batch for inspection. It is crucial to choose samples that represent the overall production quality accurately.

3. Measurement Procedure

The selected samples are carefully measured using the designated measurement equipment. The measurements are taken multiple times to minimize any potential errors.

4. Data Analysis

The measured data is analyzed to determine the bore size tolerance. Deviations from the specified size are recorded and compared against the acceptable tolerance limits.

5. Quality Control

Based on the data analysis, necessary actions are taken to ensure the sprocket wheels meet the required standards. Quality control measures may involve rework, adjustments, or rejection of non-conforming components.

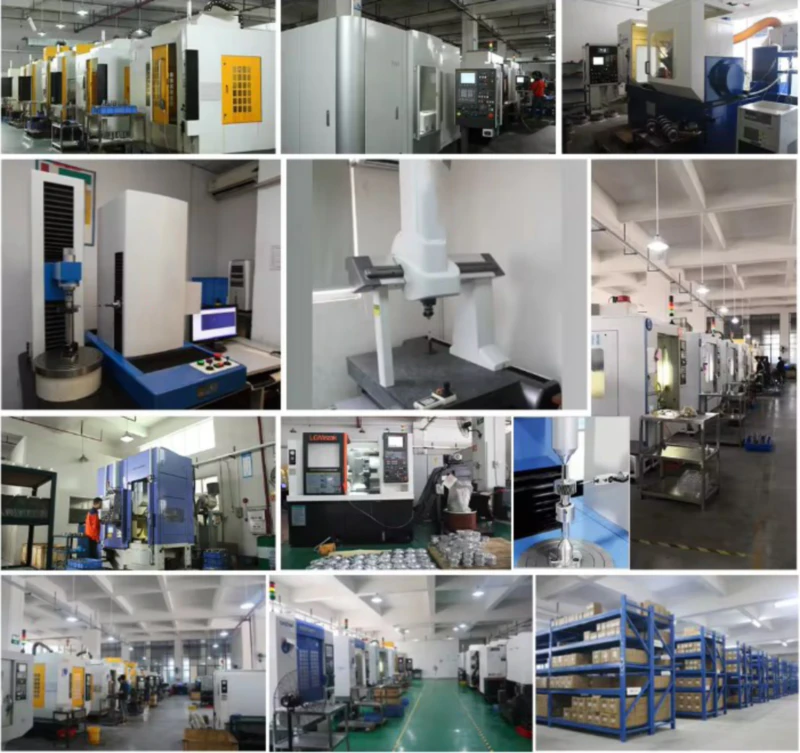

Company Promotion and Introduction

Our company is a leading player in the milling machine market in China. We specialize in the production of various mechanical components, including sprocket wheels, sprocket chains, motorbike sprockets, small sprockets, motor chains, bush chains, plastic chains, and more. With 300 sets of automated CNC production equipment and fully automated assembly facilities, we are committed to delivering high-quality products that meet stringent standards.

We take pride in offering our customers competitive prices, superior products, and excellent customer service. Customization based on customer specifications is also one of our strong points. We invite customers to provide their own designs or samples for customized production.

Author: Czh